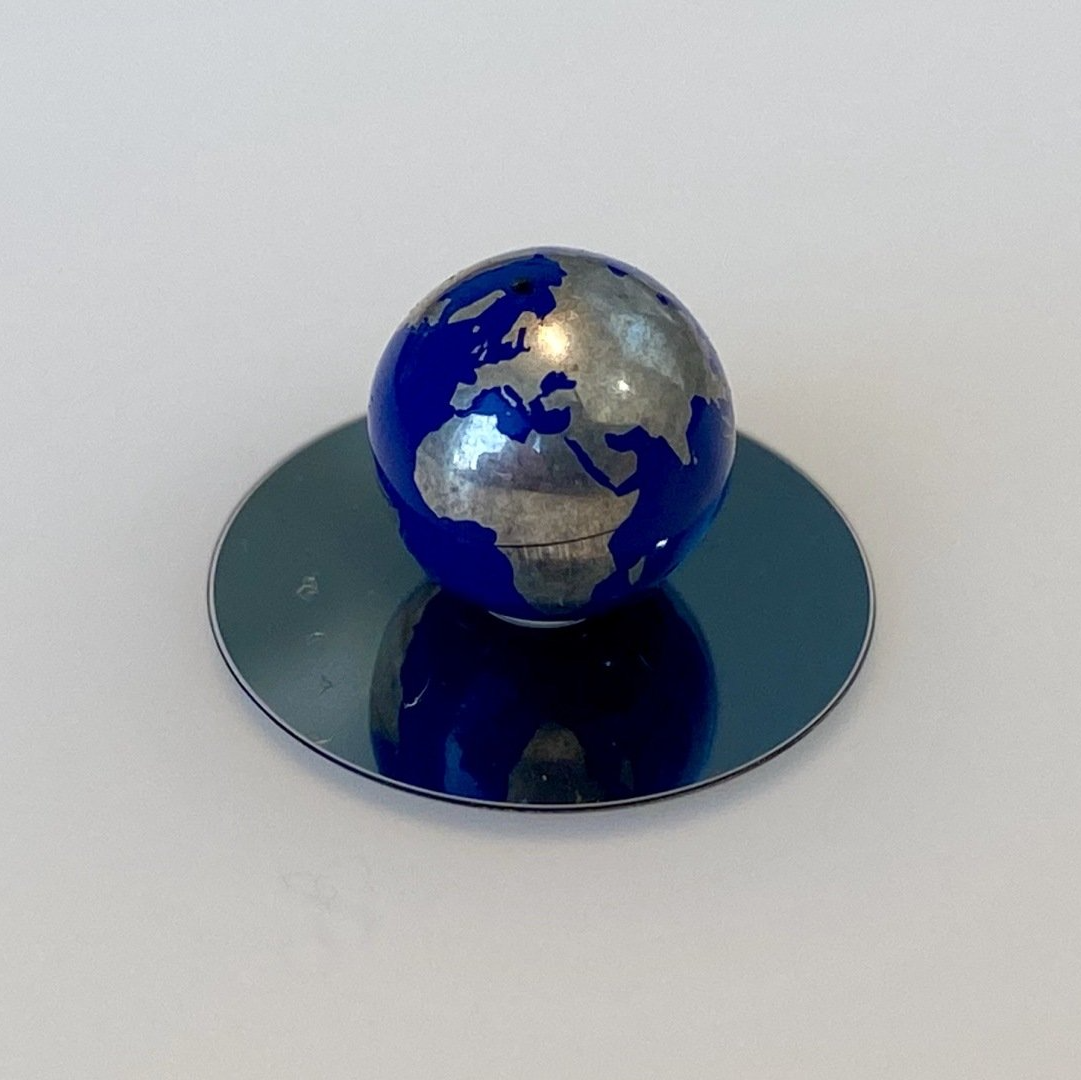

5 axis laser engraving

The luxury industries are increasingly demanding laser technologies. Whether it is for engraving one-of-a-kind pieces or for precisely repeating pieces that will be finished by hand, the laser provides an economical solution that meets these high quality requirements. Lasertec has long been developing globes engraved with a professional 5-axis laser.

The 5 Axis Laser Engraver : An Overview of What It Can Do For You.

When it comes to precision and texturing, laser engraving is unmatched by any other method. At high speeds and in tight spaces, laser engraving is a good way to get flawless, detailed designs on hard surfaces. This article will give you an overview of what a 5 axis laser engraver can do for you. If you own a business, operate a workshop, or are just curious about laser engravers, this article is for you.

What is Laser Engraving?

Laser engraving is a process of ablating material to create textures, shapes or markings on materials using a laser. There are many types of laser engraving machines, each designed for specific applications and industries.

What Can a 5 Axis Laser Engraver Do?

A 5 axis laser engraver is an industrial device that can engrave almost any materials including polymers, wood, metals, ceramics, and more. Laser machines are the most versatile and suitable for almost any type of application. With a motorised axis, the laser can move around the material to create a very detailed, accurate design. Most 5 axis laser engravers are capable of creating a large variety of symbols and designs, from text and logos to decorative patterns and artwork.

How Does Laser Engraving Work?

When a laser is used to engrave, it heats the material and sublimates the surface it touch with a really fast pulse. The speed of the pulse is directly linked with the aspect of the engraved surface you will get. The faster the pulse, the less heat will be diffused within the material. That's why you usually hear about femtosecond laser, picosecond laser or nano-laser. They all refer to the speed of the pulse frequency the laser is able to generate.

CNC 5 Axis Laser Engravers

The CNC name stands for Computer Numerically Controlled, and refers to a machine that is controlled by a computer. The computer can move the table along the X and Y axes and the Z axis. The Z axis is the direction perpendicular to the base of the machine and the table. A 5 axis laser engraver works the same way but engineers have developped 2 more rotational axis, synchronised with the focal distance of the parts in any direction.

Which 5 Axis Laser Engraver is Right for You?

The type of laser engraver you choose depends on your specific needs and requirements. If you’re looking for the most advance machine to add textures in a mold, a 5 axis laser engraver is likely what you need. On the other hand, if you plan on using your laser engraver for tasks like engraving on a flat plate, a 3 axis laser engraver is probably sufficient. When it comes to choosing the best laser engraver for your needs, it is important to consider your workflow and design requirements. At Lasertec we develop our own laser machine to be able to provide the best service quality for our customer. We also own some 5 axis machine from the GF Machining Solutions : AgieCharmilles laser.

Bottom line

If you need to get precise designs onto a wide variety of materials, a laser engraver is a good way to go. Most laser engravers can be used for a number of materials and applications, so no matter what your industry or budget, there is likely a laser engraver that will meet your needs. With the ability to engrave onto almost any surface, from metals to polymers a laser engraver is an extremely versatile tool. As the design possibilities are virtually limitless, so too is the application for a laser.