Laser Welding

Leading in micro Laser Welding

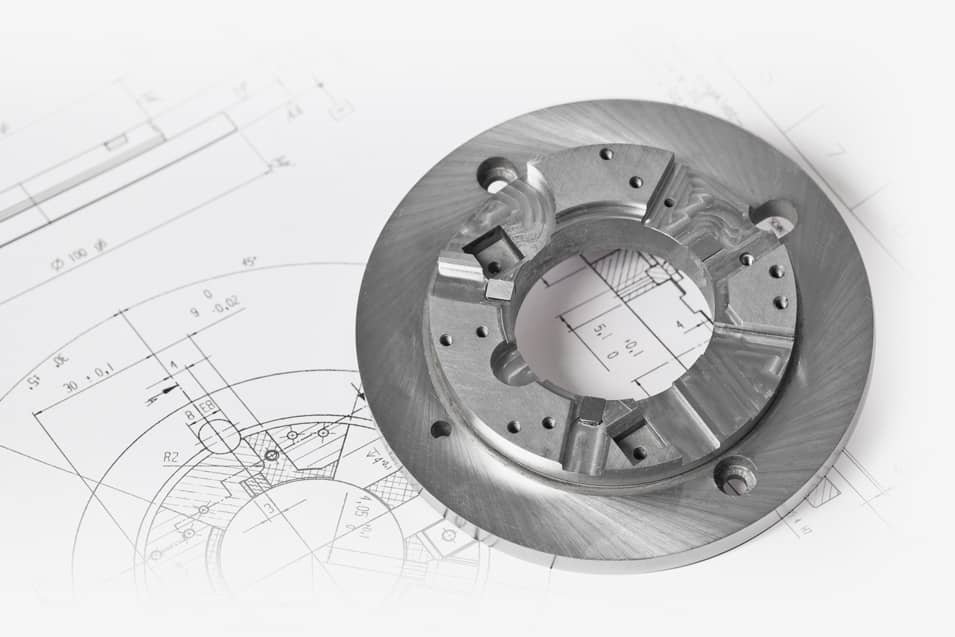

Laser welding plays a significant role in the production of precise components. This technique is applied in many industries, such as the semiconductor and watch industries. It is a method used when small parts need to be joined together with minimal heat.

What is Laser Welding?

Laser welding is a special way of welding where we use a laser beam to melt and join materials. This method is very suitable for small, sensitive parts where normal welding would be too hot. We often see microlaser welding in the making of small parts for watches, medical devices, and microscopes.

What is Laser Welding Used For?

Microlaser welding is very popular in advanced industries. Think of components for the semiconductor industry, medical devices, and precision mechanics. It is perfect for joining tricky and delicate parts, such as cooling channels and small machine components.

What is the difference between Laser Cutting and Laser Welding?

In laser cutting, material is cut using a laser, whereas the purpose of laser welding is to permanently bond things together. Laser cutting is used for slightly larger parts, while micro laser welding focuses on really small and sensitive pieces that are often almost imperceptible to the naked eye.

In Which Markets Do We Succesfully Apply it?

Laser welding is used to make components for various equipment. As previously mentioned, this includes the semiconductor world, but also measuring equipment and electron microscopes. It is also applied to analysis equipment such as a spectrograph. These are all fine mechanical parts that need to be assembled and aligned. Additionally, we often weld watch parts.

The Advantages of Micro Laser Welding

There are several advantages to micro laser processing. Firstly, little heat is generated, so the parts hardly deform. This makes it possible to work with very small materials. It is therefore suitable for connecting very small parts.

With micro laser welding, we use thin weld seams, creating strong connections without damaging the parts. Lastly, it is suitable for various materials, such as stainless steel and titanium.

Why Choose Laser Welding at Lasertec

At Lasertec, we understand the art of laser welding like no other. Laser welding is more than just melting materials together. We excel in creating dense, reliable connections, where each part is tested under high pressure or vacuum to ensure that it is helium tight. This means that each weld point must not only be strong, but also completely sealed and consistent in quality.

Our expertise lies in welding small, delicate parts. Think of fine watch components or sensitive machine components. With our advanced lasers, we can place extremely small and precise weld spots, just a few hundredths of a millimeter in size. Our team is trained to work with this precision, which is essential for ensuring mechanical strength and consistency in every welded piece.

Choosing Lasertec means opting for a partner who understands and applies the complexity and finesse of micro laser welding. With our precision, expertise, and dedication, we assure the highest quality in every weld, large or small.

Want to know more about laser welding or any of our other services? Please contact us at

+31 180 644 744

or fill in the contact form.

Process combination

Through an intelligent combination of process and know-how, we exceed the limits of what’s possible

Competences

Thanks to our years of continuous development, we offer many possibilities within our company. The laser today represents a strong and reliable process that can be adapted to different applications. Most laser capabilities are accessible within the same process. Imagine: texturing a surface, engraving your logo, and cutting parts with a single laser.

Numbers

Our success would not be achievable without a significant number of different laser

production units, years of experience and most importantly, a strong team.

More than

25

Laser production units

More than

37

People

More than

27

Years experience